BWC contracts with Ecochlor for EcoOne® Containerised BWMS solution

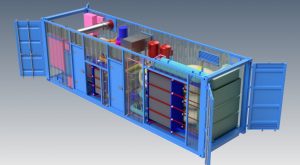

BWC contracts with Ecochlor for EcoOne® Containerised BWMS solution Ballast Water Containers has secured a contract from Ecochlor for the design and manufacture of a

BWC contracts with Ecochlor for EcoOne® Containerised BWMS solution Ballast Water Containers has secured a contract from Ecochlor for the design and manufacture of a

– Top Tip Series: BWTS Container Design – What to consider It’s no secret that when embarking on the journey of BWM compliance, there are

With 2024 deadlines approaching, why wait? As a result of an appreciation of the harmful impact, sometimes at a cataclysmic level, that ballast water may

– Top Tip Series: How seagoing barges may comply with ballast water treatment regulations Seagoing barges can’t comply with ballast water treatment regulations…or can they?

– Top Tip Series: How to mitigate the risks when addressing BWM compliance In BWC’s first tip we mentioned that in a typical BWTS project,

– Top Tip Series: Port Authorities – what can you offer as a contingency measure for vessels failing BWT inspections? If you are a port

– Top Tip Series: share the cost of ballast water treatment Do you have a fleet of vessels that operate in the same area? Maybe

– Top Tip Series: Avoid the Ballast Water Treatment System Tsunami Technology providers and class societies alike have suggested that 2022 will be one of

BWC awarded design & manufacturing contract for mobile containerized ballast water treatment system Ballast Water Containers (BWC), part of the Malin Group, are delighted to

@2020 All rights reserved